ENERGYSAVINGSERVO SOLUTION FROM From weg and Nord drive automation

In 2019 PVI introduced Hilectro Brand of Servo motors and Drives and Sumitomo (Japan) range of Internal Gear Pumps as a complete package in assembled condition imported from our principles including Coupling and Bell Housing after testing .

Trials were conducted Plastic Injection molding machines and field trials Proved that Energy savings of almost 40% – 60% depending upon application can be obtained.

Over 300000 + Installations

INTERNAL GEAR PUMP

Servo packages available60LPM to 250LPM and 160Bar as standard up to 275Bar customized on request .

IGP1,2,3 Internal Gear Pumps are from 8cc to 160cc and pressure up to 315Bar.

üIGP Series pumps are available in Tandem/Double also.Servo Vane pump series VPS and T7D/T7DS are also available and becoming popular everyday due to its high contamination retention

SUMITOMO MULTI-STAGE INTERNAL GEAR PUMP

High efficiency and energy saving equipped with a servo drive system, thereby achieving efficient and energy-saving operation.

High-quality emphasis on high-precision measurement and

inspection of components,thereby achieving high-quality products

The durablurability structure is very simple. Due to

the forced lubrication of the spreading surface of the parts, the parts are not in contact and hardly wear down, thus achieving a long service life.

The superior low noise level is low. Regardless of the

increase in pressure, number of revolutions, etc., there is little change in noise.

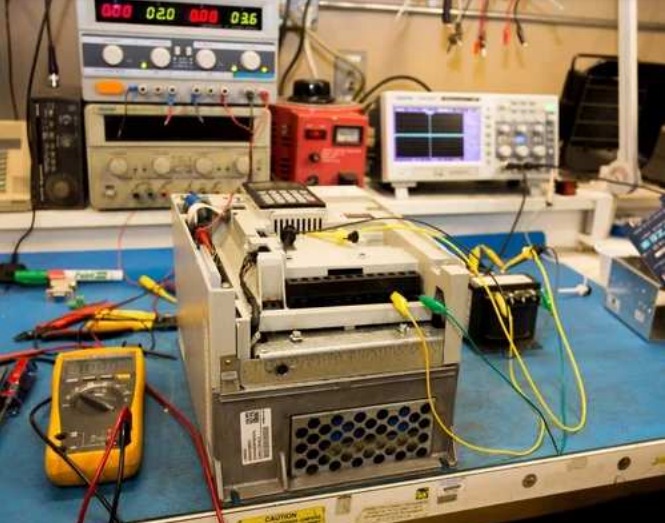

Board service - chip level

Board service at the chip level is a highly specialised and intricate process that delves deep into the heart of electronic devices. Our technicians possess unparalleled expertise in diagnosing and repairing intricate circuitry. They meticulously inspect and replace individual components, ensuring optimal performance and reliability. Cutting-edge tools and soldering techniques are employed to address even the most complex issues. The result is a rejuvenated and fully functional electronic board, ready to power your device with precision and efficiency.

Drive service and testing

Service center atmospheres

At the heart of the service center, an atmosphere of purposeful diligence prevails. Technicians, clad in crisp uniforms, navigate the bustling workspace with precision, each step in the process a carefully orchestrated move. The gentle hum of machinery underscores their expertise, while the air carries the scent of meticulous cleanliness and the faint aroma of freshly brewed coffee. On a digital display board, the progress of service orders is meticulously tracked, keeping customers informed and reassured. Within these walls, a commitment to professionalism and a well-defined process ensure that every device entrusted here leaves fully restored, and every customer departs with confidence in the quality of service provided.

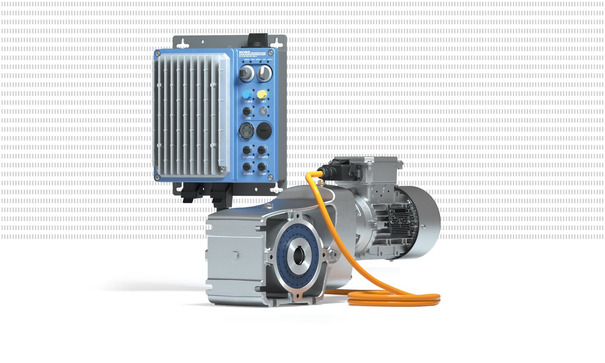

Tailored drives - suitable support

We at NORD DRIVESYSTEMS are constantly working on innovative solutions in order to meet the requirements of our customers. This results in systems such as LogiDrive being a suitable complete solution for airport applications and intralogistics, nsd tupH for drives in highly corrosive environments or the use of virtual sensors in the context of predictive maintenance.

Servo motor

The SBM series of low inertia brushless motors is designed to provide the highest level of achievable acceleration and deceleration characteristics, allowing the highest level of dynamic performance productivity and controllability, requiring a precise and ripid rapid mechanical transmission.

The SBM motors are available in six frame sizes, a wide continuous stall torque range (from 2 to 442 Nm) and speeds up to 4000 rpm.

ADL 300 DRIVE

The ADL300 series provides maximum safety, comfort and reliability for all types of civilian lifting systems in addition to its competitiveness. With modern software, developed for geared and gearless traction systems with absolute or incremental encoder, it provides exceptional control. The precise landing on the floor and the load compensation at startup provide passengers with an extremely comfortable ride. The ADL300’s compact size and operation in contactor or contactorless mode make it perfect for machine roomless applications.

ADP 200 DRIVE

ADP200 is the right solution for servopump control, providing precise pressure and flow control and avoiding the energy waste typical of traditional hydraulic systems.

Oil flow and pressure can be set exactly as required by the machine, rather than at higher levels, without discharging oil as in conventional hydraulic machines.

The ADP200 high-performance drive is perfectly in line with the innovative “green manufacturing” design of injection molding machines, creating real added value for customers in terms of energy efficiency and higher mold quality.

WEG’s specific PID algorithm manages both single servopump systems and multi-pump machines and covers a wide range of applications.

AGL 50 DRIVE

The AGL50 EV drive, available in a single mechanical size, is ideal for modernizations or new geared (asynchronous motor) low rise installations controlled in open loop, that do not require highly sophisticated control and fieldbus communication with the control card.

Easy to install and configure, the drive is a cost effective solution that ensures maximum reliability and technological quality.